-

Training

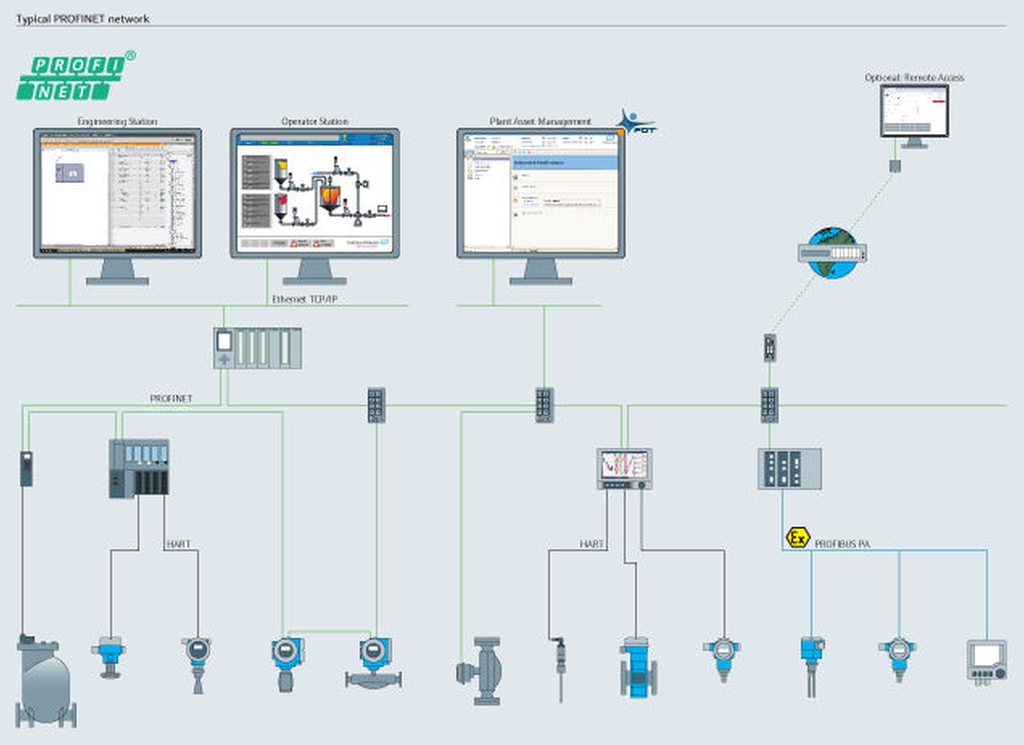

PROFINET take advantage of smart and connected devices

PROFINET fits your process needs

Using PROFINET allows the user to access added value information of multivariable devices. For example mass flow, density, temperature, totalizer settings, as well as diagnostics, can be delivered over a single cable. In addition, savings of 40% can be made through reduced commissioning time. The time spent on loop identification, device integration and process-loop tuning can also be reduced by 25%.

What are the key benefits from using Industrial Ethernet?

For engineers:

Maximized engineering efficiency, e.g. lowering system integration costs.

Minimized commissioning time, e.g. by configuring all devices directly from the system.

For operators and maintenance personnel:

Increased operational performance, e.g. by providing richer real-time data.

Improved maintenance processes, e.g. by directly accessing device diagnostics.

Highlights

All Endress+Hauser PROFINET devices certified by PI to ensure perfect interoperability.

Device driver (GSD) directly stored in device.

Defined modules and well structured information available within control system

as clear-text.

Immediate device recognition as a network node.

Integrated web server for diagnostics and remote access.

Predictive maintenance support by providing reliable diagnostic data acc. to NAMUR NE 107.

Start-up records for automatic configuration at device exchange.

Your Benefits

Web server:

Time-saving local operation without additional software.

Comprehensive access to device, diagnostics and process information.

Fast data upload/download for maintenance and service.

Simple operation:

Time-saving Endress+Hauser operating concept.

Optimal usability through guided parameterization.

User-specific menu structures and device access.

PROFINET unifying automation networks

Scalability in your plant.

Flexibility and modularity in your installation.

Seamless data accessibility.

Transparency of field device information from the shop floor to the board room.

Investment protection with integration of all process networks.

Openness with PROFINET

The standard IEC 61158 und IEC 61784-2 provides a full, open, manufacturer-independent and stable basis for your investments.

The technology is proven in practice with an installed base of over 12 million devices worldwide.

PROFINET products have to be tested and certified in independent laboratories accredited by the PROFIBUS and PROFINET User Organization (PI).

For detailed information: www.profinet.com

PROFINET transforms your data into information

-

Standard products

- Reliable, robust and low-maintenance

Technical excellence

Simplicity

-

Specialized products

- Designed for demanding applications

Technical excellence

Simplicity

Variable

| FLEX selections | Technical excellence | Simplicity |

|---|---|---|

Fundamental selection Meet your basic measurement needs |

Technical excellence

|

Simplicity

|

Lean selection Handle your core processes easily |

Technical excellence

|

Simplicity

|

Extended selection Optimize your processes with innovative technologies |

Technical excellence

|

Simplicity

|

Xpert selection Master your most challenging applications |

Technical excellence

|

Simplicity

Variable |

Downloads

-

PROFINET take advantage of smart and connected devices

Take advantage of smart and connected devices with PROFINET. Transform your data into information.

File size:

File name: